Indirect Solar Dryer

Development of novel and economical Indirect Solar Dryer for food preservation

Methodology & Design

Problem Statement

The objective of this study is to Development of Novel and Economical

Indirect Solar Dryer for Food Preservation. The system aims to improve

the shelf life and quality of dried foods such as bananas, potatoes,

etc. by effectively reducing their moisture content.

System Design

Design a solar dryer system with the following features:

a. Two different airflow configurations:

Exhaust Air Flow:

The exhaust fan is placed at the back to release all the additional

air or heat.

Cold Airflow:

The inlet fan is placed at the front to intake

all the air while maintaining the desired temperature.

b. Conventional trays:

Used a wooden tray to hold and arrange the food for drying.

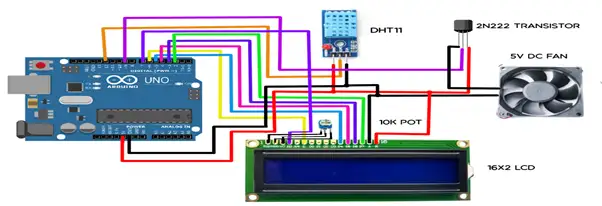

c. Component Selection Air Circulation fan:

Select a fan capable of providing the desired air flow rates for

efficient drying. Temperature and humidity sensors: Used a DH11 sensor

to monitor and control the drying environment.

d. Arduino Integration:

• Integrate an Arduino microcontroller into the system to control the

operation of the drying system, including:

• Connected the DH11 sensor to measure and monitor the temperature and

humidity levels inside the dryer.

• Connected the motor driver to control the air circulation fan,

adjusting the fan speed based on the desired drying conditions.

• Connected display to the I2C module to reduce wires and connected it

to the Arduino Board.

Hardware Requirements

• A sealed box according to the required dimension.

• The top surface of the dryer is covered by a polycarbonate sheet.

• Two fans to transfer the hot air from the collector to the dryer and

in letting the cold air.

• Zeolite Bed.

• Arduino-Based Automatic Control System.

• Male-Female Wire

• Motor Driver

• Fans

• Temperature cum Humidity Sensor DTH 11

• Digital Display

• I2C Module

• 12v Adapter

Arduino and Programming

Arduino is an open-source electronics platform that consists of both

hardware and software components. It was designed to provide an

accessible and user-friendly platform for creating interactive

projects and prototypes. Arduino boards are equipped with

microcontrollers that can be programmed to control various electronic

devices and interact with sensors and actuators.

In our project, we are utilizing Arduino as a crucial component for

controlling and monitoring various aspects of our system. Arduino

serves as the central control unit that enables us to automate and

regulate the drying process.

Arduino's flexibility, reliability, and extensive community support

make it an ideal choice for our project. It enables us to create a

customized and efficient drying system that meets our specific

requirements, ultimately contributing to improved food preservation

and economic viability in agricultural communities.

By combining the power of Arduino with these components, we can

automate the control of the Drying System. Arduino's programmability

and ability to interface with sensors, motors, and displays allow us

to precisely regulate temperature, humidity, and airflow. We can also

collect and analyze data from different sensors to optimize the drying

process and ensure the quality of the dried food products.

Programming the Arduino

Programming the Arduino is a crucial step in implementing the

functionality of the solar dryer. Here's an overview of the process:

• Install the Arduino IDE:

Download and install the Arduino Integrated Development Environment

(IDE) from the official Arduino website. The IDE is a software

platform that allows you to write, compile, and upload code to the

Arduino board.

• Connect the Arduino Board:

Connect the Arduino board to your

computer using a USB cable. Ensure that the board is properly

recognized and detected by the computer.

• Open the Arduino IDE:

Launch the Arduino IDE software on your computer. You will be

presented with a blank sketch (program) window.

• Write the Code:

In the Arduino IDE, write the code that defines the behavior and

functionality of the solar dryer. This may include reading sensor

data, controlling the motor driver, managing user inputs, and any

other tasks required for proper operation.

• Verify and Compile the Code:

After writing the code, click

on the "Verify" button in the Arduino IDE to check for any syntax

errors or issues. The IDE will compile the code and display any error

messages if present. Address any errors or warnings before proceeding.

• Upload the Code to the Arduino Board:

Once the code has been

verified and compiled successfully, click on the "Upload" button in

the Arduino IDE. This will compile the code again and upload it to the

Arduino board. The board's built-in bootloader will receive and store

the code in its memory.

• Monitor the Serial Output:

Use the serial monitor feature in

the Arduino IDE to monitor and debug the code's output. This can help

troubleshoot or verify sensor readings, motor control, or any other

data transmitted or received by the Arduino.

• Test and Refine the Code:

Disconnect the Arduino from the

computer and connect it to the solar dryer circuit. Power up the

system and test the functionality of the code. Make adjustments and

refinements as needed to achieve the desired behavior and performance.

• Iterate and Update the Code:

As you test and gather feedback

on the solar dryer's performance, make any necessary updates or

modifications to the code. Refine the logic, improve efficiency, or

add new features to enhance the overall functionality of the solar

dryer.

• Document and Backup the Code:

It is essential to document the

final version of the code for future reference. Save a backup of the

code in a secure location and maintain proper version control to track

any changes made over time.

Connection to Arduino

The Arduino Board is a versatile microcontroller that can be used to

connect and control sensors, motors, and displays. In this case, we

will discuss the connections between the Arduino board, the DHT11

sensor, the motor driver, I2C and Display, along with the

corresponding data pins.

The DHT11 Sensor:

• The DH11 sensor's data pin is connected to digital pin 12 of the

Arduino.

Motor Driver (L298N) & Fan:

The exhaust fan and the cooling fans are connected to the motor

driver.

• IN1 of the motor driver is connected to the 2nd pin, which is

denoted by the Purple wire.

• IN2 is connected to the 3rd pin, represented by the Blue wire.

• IN3 is connected to the 4th pin, indicated by the Green wire.

• IN4 is connected to the 5th pin, designated by the Yellow wire.

• ENA (Enable A) is connected to the 9th pin, which is represented by

the Grey wire.

• ENB (Enable B) is connected to the 10th pin, denoted as ENB.

Display & I2C Module:

The display is connected to Arduino using I2C Module. The connections

typically involve connecting the required data pins (such as data,

clock, and control) of the display module to the corresponding pins on

the Arduino.

• The SDA (Serial Data) pin of the I2C sensor is connected to the

Arduino's A4 pin, represented by the Orange wire.

• The SCL (Serial Clock) pin of the I2C sensor is connected to the

Arduino's A5 pin, also denoted by the Orange wire.

By establishing these connections, the Arduino can effectively

communicate with the DH11 Sensor, motor driver, display, fan, and I2C

sensor. This enables the control and monitoring of various aspects of

the system.

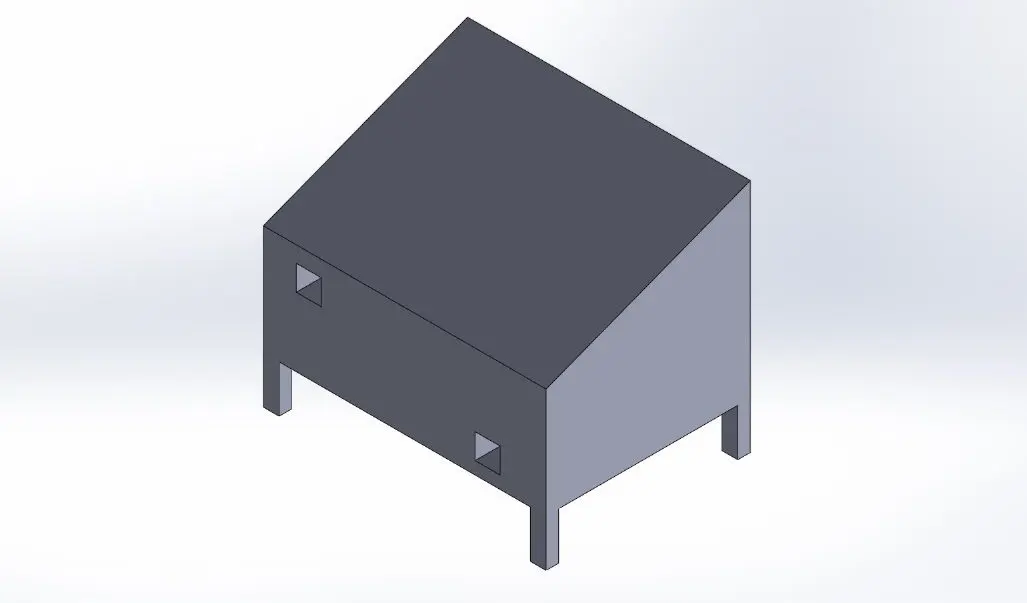

Design Consideration

SolidWorks

SolidWorks is a powerful Computer-Aided Design (CAD) software widely

used in various industries for designing and modeling

three-dimensional (3D) objects and assemblies. It provides a

comprehensive set of tools and features that enable engineers and

designers to create, simulate, visualize, and analyze their designs

with precision.

SolidWorks played a crucial role in the design process. Here are some

key aspects and benefits of using SolidWorks:

3D Modeling:

SolidWorks allows users to create detailed 3D models of their designs.

This includes designing individual components of the solar dryer, such

as the zeolite beds, polycarbonate sheets, fan, motor driver, and

other relevant parts. These components can be accurately modeled with

their specific dimensions, shapes, and features.

Assembly Design:

SolidWorks facilitates the assembly of different components to create

a complete system. Users can easily assemble the individual parts of

the solar dryer, ensuring proper fit, alignment, and functionality.

This helps in visualizing how all the components come together and

interact with each other.

Visualization and Rendering:

The software provides realistic visualization capabilities, allowing

designers to render high-quality images and animations of the solar

dryer. This helps in creating visually appealing representations of

the design, showcasing its appearance, materials, and textures.

Simulation and Analysis:

SolidWorks offers simulation tools that enable engineers to perform

virtual testing and analysis of their designs. This includes

conducting structural analysis to ensure the integrity and strength of

the components, as well as thermal analysis to evaluate the heat

transfer and temperature distribution within the dryer.

Design Optimization:

With SolidWorks, designers can iterate and refine their designs based

on the simulation results and analysis feedback. This allows for

design optimization, where potential issues or weaknesses can be

identified and addressed early in the design process, leading to

improved performance and efficiency of the solar dryer.

Documentation and Communication:

SolidWorks facilitates the creation of detailed drawings, technical

documentation, and bills of materials for the solar dryer. These can

be shared with stakeholders, manufacturers, or collaborators, ensuring

clear communication and accurate manufacturing specifications.

Drying Chamber:

The drying chamber should be designed to fit the dimensions provided.

It should be made of durable, non-toxic, and easy-to-clean materials,

such as stainless steel or food-grade plastic. In this case, a zeolite

bed can be used as the drying medium.

Airflow:

Airflow is critical for efficient drying. To achieve good airflow, two

CPU fans can be used. One fan can be placed at the bottom of the

drying chamber to draw in the fresh air, while the other can be placed

at the top to exhaust the moist air. The airflow rate should be

approximately 2.5 to 3 cubic meters per minute per square meter of

drying area.

Cover:

A polycarbonate sheet can be used as a cover to allow solar radiation

to enter the drying chamber. The sheet should be positioned at an

angle to maximize solar exposure.

Insulation:

To minimize heat losses, the walls and roof of the drying chamber

should be insulated with a layer of foam or other suitable material.

Control system:

A control system can be added to monitor temperature and humidity

levels inside the drying chamber. This can help to optimize the drying

process and ensure that the product is not over-dried.

Construction

Angle cutting according to the size of CAD Drawing:

In this step, the angles required for constructing the solar dryer were cut to specific sizes based on the dimensions provided in the CAD drawing. The angles were carefully measured and marked before being cut using appropriate cutting tools such as a miter saw or angle grinder. Precision and accuracy were maintained to ensure that the angles fit together properly during the assembly process.

Joined the angles using Arc Welding:

Once the angles were cut, they were joined together using arc welding. Arc welding is a process that utilizes an electric arc to create a high-temperature fusion between metal components. It provides a strong and durable bond between the angles, ensuring structural integrity. Skilled welders performed the welding process, adhering to safety precautions and following welding procedures to achieve high-quality weld joints.

ARC Welding:

Arc welding is a widely used welding technique that

plays a crucial role in the construction of the solar dryer in our

project. It involves the use of an electric arc to create a

high-temperature fusion between metal components, resulting in a strong

and durable weld joint. Here's an explanation of arc welding with our

project:

Joining Metal Components:

In the construction of the solar dryer, various metal components, such

as angles, steel sheets, and frames, need to be joined together to form

the structure of the dryer. Arc welding is employed to fuse these

components, ensuring their structural integrity and stability.

Arc Welding Process:

The arc welding process involves the use of an electric power supply,

typically an arc welding machine, that generates a controlled electrical

current. A welding electrode, also known as a welding rod or filler

metal, is held in contact with the metal components to be joined. When

the electrode comes into contact with the metal and an arc is struck,

the intense heat melts the metal and the filler metal, creating a weld

pool. As the weld pool cools, it solidifies, forming a strong bond

between the joined components.

Benefits of the Project:

Arc welding provides several benefits within our project:

Strength and Durability:

The arc welding process produces robust and durable weld joints,

ensuring the structural integrity and longevity of the solar dryer.

Customization and Flexibility:

Arc welding allows for the precise and customizable joining of various

metal components, enabling the construction of the solar dryer according

to specific design requirements.

Time and Cost Efficiency:

Arc welding is a relatively fast and efficient welding process, making

it suitable for large-scale production or construction projects like our

solar dryer. It also offers cost advantages compared to other welding

methods.

Versatility:

Arc welding can be performed on a wide range of

metals, including steel, stainless steel, and aluminum, providing

versatility in the construction of the solar dryer and allowing for

compatibility with different materials used in the project.

Formed the boundary structure of the Indirect Solar Dryer:

By connecting the welded angles, the boundary structure of the solar dryer was formed. This structure provided the framework for supporting the other components of the dryer, such as the zeolite beds, polycarbonate sheets, and other elements. The angles were aligned and secured together using welding techniques, ensuring stability and rigidity of the overall structure.

Cut the steel sheet using a grinder tool according to the desired dimensions of the solar dryer (as per CAD Drawing):

To create the outer enclosure of the solar dryer, steel sheets were cut to the desired dimensions specified in the CAD drawing. A grinder tool, equipped with an appropriate cutting wheel, was used to make precise cuts on the steel sheets. Care was taken to follow the dimensions accurately, ensuring that the cut sheets fit perfectly within the boundary structure of the dryer.

Welded the sheets inside the Indirect Solar

Dryer:

Once the steel sheets were cut, they were welded inside the boundary

structure of the solar dryer. The sheets formed the walls and surfaces

of the dryer, enclosing the internal components. Welding techniques were

employed to join the cut steel sheets securely to the framework,

creating a sealed and robust enclosure. The welding process involved

melting the edges of the steel sheets and fusing them with the existing

structure, ensuring a strong and leak-proof assembly.

Fixing the Polycarbonate sheet at the top:

To fix the polycarbonate sheet in our project, we used self-groove

screws.

Self-groove screws are specifically designed for securely fastening

materials like polycarbonate sheets. Here's how we will utilize these

screws:

Preparing the Polycarbonate Sheet:

Ensure that the polycarbonate sheet is cut to the desired dimensions and

properly aligned with the frame or structure of the solar dryer.

Positioning the Screws:

Determine the locations where the polycarbonate sheet will be attached

to the frame. Mark these positions on the polycarbonate sheet and

corresponding spots on the frame to ensure accurate placement.

Drilling Pilot Holes:

Use a drill with an appropriate-sized drill bit to create pilot holes at

the marked positions on the polycarbonate sheet and the frame. The pilot

holes should be slightly smaller than the diameter of the self-groove

screws to provide a secure fit.

Aligning the Polycarbonate Sheet:

Place the polycarbonate sheet over the frame, aligning the pilot holes

on the sheet with the corresponding holes on the frame.

Inserting the Self-Groove Screws:

Take a self-groove screw and insert it into one of the pilot holes.

Apply gentle pressure while turning the screw clockwise to drive it into

the polycarbonate sheet and secure it to the frame. Repeat this process

for all the pilot holes.

Tightening the Screws:

Use a screwdriver or a power drill with a suitable screwdriver bit to

tighten the self-groove screws. Be cautious not to overtighten, as it

may cause damage to the polycarbonate sheet. Ensure that the screws are

snugly secured, holding the polycarbonate sheet firmly in place.

Repeat for Remaining Holes:

Repeat the screw insertion and tightening process for all the remaining

pilot holes, ensuring an even and secure attachment of the polycarbonate

sheet to the frame.

Self-groove screws have a unique design that creates a tight and secure

connection between the polycarbonate sheet and the frame. The grooves on

the screw thread provide a better grip and prevent slippage, ensuring

that the polycarbonate sheet remains firmly fixed in place.

By using self-groove screws, we can effectively and securely fix the

polycarbonate sheet, providing structural integrity to the solar dryer

and protecting the contents inside from external elements.

Painting the Body of the Indirect Solar Dryer:

After the construction of the indirect solar dryer using the steps

mentioned earlier, the next step in the process is painting the dryer.

Painting not only enhances the appearance of the dryer but also provides

protection against corrosion and extends its lifespan. The painting

process typically involves using a primer as a base and applying black

paint on top of it.

Priming:

The first step in painting the Indirect Solar Dryer is applying a primer. Primer acts as a preparatory coating that promotes better adhesion of the paint and improves its durability. It helps to create a smooth and even surface for the subsequent layers of paint. The primer is evenly applied to the entire surface of the dryer, ensuring that all areas are adequately covered. It is allowed to dry completely according to the manufacturer's instructions.

Adding Black Paint:

Once the primer has dried, the next step is to apply black paint. Black paint is commonly chosen for solar dryers due to its ability to absorb sunlight efficiently. The black color helps to enhance the absorption of solar radiation, thereby increasing the heating efficiency of the dryer. It also gives the dryer a sleek and professional appearance. The black paint is applied over the primed surface using a paintbrush.

Adding Grey Paint:

Adding Grey Paint for the inside of the Indirect Solar Dryer provides

additional benefits to the overall functionality and performance of the

system. The grey paint is applied to the inside of the Solar Dryer. Grey

is chosen as the color for the interior as it helps to reflect and

distribute the light more evenly. This aids in maintaining a uniform

temperature inside the dryer, which is crucial for the effective and

consistent drying of agricultural products.

The grey paint for the inside of the solar dryer contributes to its

functionality by reflecting light and heat more evenly, which helps

maintain a balanced drying environment. It also provides a protective

barrier for the interior surface, enhancing its durability and

resistance to moisture or other potential sources of damage.

Finishing touches:

Once the black paint has dried completely, the painting process is

complete. However, it is important to ensure that the painted surface is

smooth and free from any imperfections. Inspecting the dryer for any

drips, uneven areas, or rough spots and performing any necessary

touch-ups will help achieve a clean and professional finish.

By properly priming and adding black paint to the Indirect Solar Dryer,

grey paint on the inside surface becomes an integral part of the overall

construction. It not only enhances the visual appeal of the dryer but

also contributes to its functionality by optimizing solar radiation

absorption.

These steps in the construction of the solar dryer involved precise

cutting, welding, and assembly techniques. Skilled craftsmen and welders

played a crucial role in accurately executing these steps, following the

specifications provided in the CAD drawing. The result was a sturdy and

well-constructed solar dryer with a boundary structure and steel sheet

enclosure, ready to accommodate the internal components and facilitate

the efficient drying of agricultural products.

Fixing up the components

To integrate and secure all the Arduino-related components in the solar

dryer, we can use a glue gun and proper wiring techniques. Here's a

step-by-step process for fixing the Arduino components:

• Prepare the Arduino Components: Gather all the Arduino-related

components, including the Arduino board, sensors, motor driver, and any

other electronic devices that need to be connected.

• Plan the Placement: Determine the optimal locations within the solar

dryer to position the Arduino components. Consider factors such as

accessibility, space availability, and wiring requirements.

• Clean and Prepare the Surface: Ensure that the surface where the

components will be mounted is clean and free from any dust or debris.

This will help the glue adhere properly.

• Apply Hot Glue: Heat the glue gun and apply hot glue to the desired

location for mounting each Arduino component. Be careful not to use

excessive glue that may obstruct the functionality or wiring of the

components.

• Attach the Components: Place the Arduino board, sensors, motor driver,

and other electronic devices onto the hot glue while it is still

pliable. Press them gently to secure them in place. Ensure that the

components are aligned correctly and positioned as planned.

• Allow the Glue to Cool and Set: Let the hot glue cool down and

solidify, ensuring that the Arduino components are firmly attached to

the surface. This will provide stability and prevent movement during

operation.

• Connect the Wiring: Use appropriate wiring techniques to connect the

various Arduino components. This may involve using jumper wires,

connectors, or soldering, depending on the specific requirements of your

project. Follow the recommended wiring diagrams or instructions for each

component.

• Organize and Secure the Wiring: Arrange and secure the wiring neatly

to avoid tangling or interference. Use cable ties or adhesive clips to

bundle and fasten the wires along the desired paths. This will help

maintain a clean and organized setup.

• Test the Connections: Before closing the solar dryer, double-check all

the wiring connections and ensure that they are correctly connected to

the Arduino board. Test the functionality of each component to verify

that they are working as intended.

• Using a glue gun provides a convenient and non-permanent method for

mounting the Arduino components, allowing for easy removal or

repositioning if necessary. However, ensure that the glue does not

obstruct access to ports, buttons, or other critical components that may

require interaction or maintenance.